Starting with a plan for your air compressor's intended purposes is a good place to be. The next critical step is to identify the applicable tools and create a list of their uses. Ultimately, you'll want to arm self with the correct knowledge to use your air supply properly, and that means doing considerable research here on tools, output, and usage when selecting a compressor.

The cubic feet per minute (cfm) air consumption standard and the operational pressure of tools that will be used with the compressor will serve as the basis for this investigation. There are a few key features to look for when shopping for a portable compressed air to make sure you get the proper one. Air quality and pressure, tank size, pressure cycling, and duty cycle are also important factors.

While it's possible for people to figure these out on their own, it's always smart to see an expert just to be sure. Here at Mobile Power Australia, we have a large selection of portable air compressors for both home and commercial use. Providing helpful guidance to clients is a passion of ours, therefore we've compiled a detailed checklist of requirements for portable air compressors.

FAQs About Choosing An Air Compressor

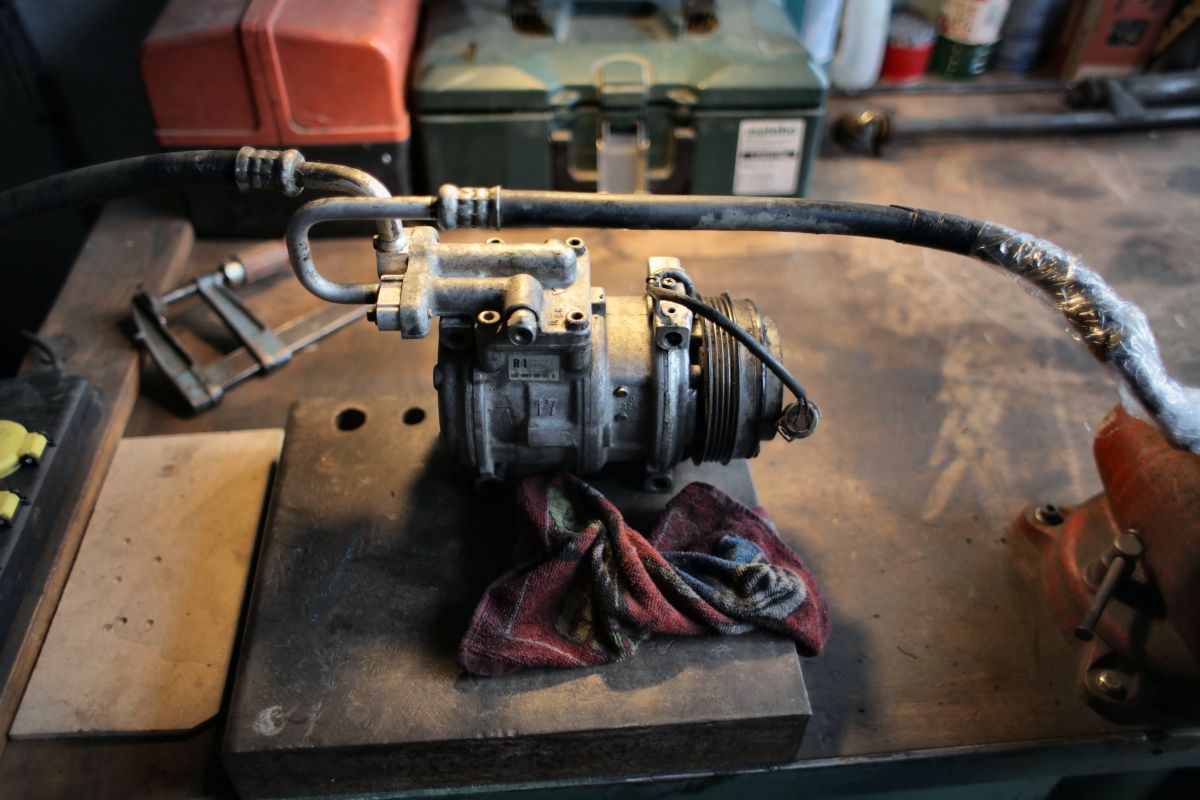

To use air tools such as paint guns, impact wrenches, air nailers, and even tyre inflators, you'll need a compressor to run everything. Since it's the heart of any air tool setup, your compressor will need to be capable of meeting the requirements of your tools - which means that you need to buy one that's the right size and is powerful enough to do the job.

Are you going to be carrying out major projects or just an odd job? Primarily automotive maintenance or some home construction? The more involved and varied the tasks you'll need to run air tools, the more likely you will require a larger and more powerful compressor.

Are you going to be sanding and painting? Or running things like wrenches and nailers? Generally speaking, tools that require a constant air supply such as paint guns, sandblasters and grinders will need a compressor with a bigger tank. Also, the more power your tools need to put out, the more airflow your compressor will need to provide them.

If you only intend to work in one place, you can often run hoses of suitable length and keep your compressor in one spot. However, if you intend to work in other locations, be sure to consider the weight and portability of your compressor. Another thing to consider is the noise output of your compressor - the larger and more powerful they are, generally, the louder they are, and the different drive systems will also impact the noise output. Once you have this information in mind, you'll have a good idea of what size of air compressor is best for you.

The amount of airflow an air compressor produces is One of the most important ratings you'll need to consider when choosing your compressor. To find out which air compressor can run which tools, you'll need to know the "LPM" requirements of the tools you'll be using. LPM stands for litres per minute and refers to the air that a compressor can output. Most air tools come with this LPM reading on their packaging to make it easy to match the air tool to the compressor.

Choosing The Right Compressor

You may save both time and cash in the long run by purchasing a high-quality compressor that is well suited to your demands. Doing so is straightforward and requires an awareness of a few basic ideas. Using this manual, you can improve the odds of making a wise investment.

There are four primary considerations when deciding on a compressor:

- The sum of the air needs of all the tools you intend to run off of the compressor at once.

- In other words, the pressure at which your tools are supposed to be working.

- Whether or whether you plan to run your air tools constantly or only when absolutely necessary.

- Your worksite's accessibility to electricity and whether or not you'll require a portable unit are two important considerations when purchasing power tools.

Tool Air Consumption

In order for an air tool to function properly, it requires a steady supply of pressurised air from a compressor. So, the air tools you plan on using will be a driving element in deciding which compressor to purchase. The amount of air that can be used with an air tool is specified, and is often given in litres or cubic feet per minute. In addition, their working pressure is specified in bars (b) or psi. A common air saw, for instance, may have a pressure requirement of 6 bar (90psi) and an air consumption rate of 170 l/min (6cfm). To learn how much air a specific tool needs, you'll need to reference the tool's user handbook or the manufacturer.

In order for an air tool to function properly, it requires a steady supply of pressurised air from a compressor. So, the air tools you plan on using will be a driving element in deciding which compressor to purchase. The amount of air that can be used with an air tool is specified, and is often given in litres or cubic feet per minute. In addition, their working pressure is specified in bars (b) or psi. A common air saw, for instance, may have a pressure requirement of 6 bar (90psi) and an air consumption rate of 170 l/min (6cfm). To learn how much air a specific tool needs, you'll need to reference the tool's user handbook or the manufacturer.

Compressor - Free Air Delivery (Fad)

To meet the air consumption needs of the tool or tools, a compressor must provide an enough volume of air. Compressor output, or Free Air Delivery (FAD), is specified in litres per minute. How much air a tool needs to operate is directly related to the FAD. A compressor's FAD rating of at least 170 e n is required, for instance, to meet the air demand of an air saw that uses 170 l/min of air.

In order to ensure that your compressor can keep up with the total air impact made by all of your concurrently running equipment, you need add up their individual air consumption figures. A pump with a FAD of at minimum 283 l/min (170 + 113) is required, for instance, to power both an air cut (170 l/min) or an air ratchet at the same time.

Air Pressure & Quality

Tools require pressurised air, which can only be provided by a compressor. When a tool needs air pressure of 12 bar (174 psi), for instance, you'll need a generator that can generate that level of pressure. But, a pressure regulator attached to the compressor may allow you to reduce the air supply to reduced density if the tool requires only 6 bar (90psi).

- Tools that aren't designed to withstand high pressure can be damaged by it.

Cabin pressure and quality are crucial considerations when shopping for an air compressor. An air compressor's effectiveness depends on its ability to supply adequate quantities of pressurised air to the attached tools.

If a tool needs air at 174 psi, for instance, your compressor needs to be able to produce air at that pressure. Similarly, if a tool only requires 80 psi, a tool with a higher psi rating can be adjusted to produce a lesser pressure. So, it is recommended that the air compressor be purchased in accordance with the highest-pressure tool that will be used.

Air Quality

While using a compressor, air quality can be adjusted. Unfiltered air may contain dust, water, and oil particles. Think about getting a compressor with built-in particle and humidity filters if your tools or application calls for "clean" air. There is also the option of oil-free pumps, which eliminates any potential for oil to get into the air. The air quality of the compressed air you produce is another matter entirely. Due to the fact that compressors can generate air of different quality, contaminants like dust, moisture, and oil particles may be present with in airflow if the compressors is not of high quality. The risk of polluted air can be reduced by selecting a pump that has particles and moisture filters already installed.

Tool Usage

The third thing to think about before purchasing a compressor is what you'll be using the compressor for. Depending on how you plan to use a tool, its air consumption could vary significantly. If you're using an air saw, for instance, and you're running it in long, continuous bursts rather than short, intermittent ones, you'll need to supply it with more air to keep it running smoothly and efficiently.

Pressure Cycle

For the most part, compressors work by pumping pressurised air into the tank up until the pressure reaches a preset maximum. Because of the loss of pressure so when compressed air is consumed by a tool, the compressor kicks on to re-pressurize the tank when it hits its lower pressure limit. The pressure cycle of a compressor looks like this. The heat generated during the compression process poses a threat to the compressor's integrity if it is not properly controlled. Compressors might cool down while a water in the tank is used up after being turned off.

Due to the necessity to turn on the unit to repressurize the storage space, the cooling down period is shortened when a tool rapidly depletes the air supply. If the cooling down period is rushed, the compressor could overheat and break.

Duty Cycle

Duty Cycle refers to the ratio of time spent pressurising to time spent cooling down. A compressor's duty cycle, the ratio of its on time to its off time, should never exceed 60% for maximum operating life. You should get a compressor with a higher Afs rating and an extra storage tank if you want to consistently use high air consuming tools, as doing so will lessen the risk of wear and overheating.

Where Do You Want To Use The Compressor?

Consideration of the location where the compressor and equipment will be used is the fourth most important factor.

Portability

Do you require a compressor that can be taken with you? Your compressor's size, power, and output volume will all be constrained by the need for portability.

The Advantages of Electricity Over Gasoline-Powered Vehicles

Outdoor uses, or those that can't access electricity, are where a petrol compressor really shines. You should never use one in an confined space. A compressor powered by an electric motor, on the other hand, is more cost-effective both initially and over time, not to mention easier to maintain. Be sure you have enough electricity to run an electric compressor if that's the one you decide to go with. In order to function, your compressor may need power at either 10 or 15 amps, or even at 3 phases.

Measurement of Tank Capacity

Your compressor's tank size needs to accommodate the compressor's capacity as well as any attachments you want to employ. A tool used in brief, infrequent bursts, for instance, just needs a tiny tank because the air volume won't be depleted quickly. However, a greater tank is recommended if your compressor will be in use for extended periods of time. A larger tanks will reduce your manoeuvrability, so keep that in mind.

Geographical Position

The intended site for the compressor must be spacious enough to accommodate the unit, with sufficient airflow to prevent overheating.

Industrial-Scale Fabrication Facilities

So, let's say you need air for an industrial uses or want to set up a huge air system with much more than five workstations. Talk to a member of the Total Tools team, and they'll give you the guidance you need to put together a system that's tailor-made to your specific demands, which may involve a screw pump and a unique arrangement of air ducts and filters.

Other Things You Should Know

- Rather than producing air, the tank merely stores it. A larger tank takes longer to complete its cycle and doesn't provide any additional air volume.

- Using too much force for the task at hand is inefficient and can lead to tool failure.

- If you have access to three-phase electricity, you should invest in a three-phase compressor.

- To avoid wasting energy, avoid using extension cords and go for a longer air hose instead.

- Consider a fuel compressor as an alternative to a long extension cord.

- Compressor failure is often caused by overheating, therefore it's important to keep the unit well-ventilated and easy to get to for servicing.

- To convert FAD to CFM, divide by 28.3

Using An Air Compressor

Using and maintaining your air compressor will be a breeze if you keep in mind a few key points after making your purchase.

- You should stay away from the use of extension cords. You should utilise a bigger air hose if you need to increase the distance your compressor can reach.

- If you want to keep the compressor's duty cycle within safe limits, you shouldn't use the air instrument while the pump is running. Do not proceed with the task on until pump has stopped running.

Conclusion

In the long run, you may save time and money by selecting a high-quality compressor that is tailored to your needs. The volume of air that may be used with an air tool, the pressure at which the tools are meant to be operating, the availability of electricity at the workplace, and whether or not a portable unit will be necessary, are the four key considerations when choosing a compressor. Compressor output, also known as Free Air Delivery (FAD), is measured in litres per minute; an air saw that consumes 170 l/min of air necessitates a compressor with a FAD rating of at least 170 e n. Total up the air usage of all of your running machines to make sure the compressor can keep up with the demand.

The cabin's pressure and quality, the air quality, the tools to be used, and the pressure cycle are all factors to think about when searching for an air compressor. Air quality can be modified by choosing a compressor with built-in particle and humidity filters and oil-free pumps, and cabin pressure is important for giving sufficient pressurised air to the attached tools. Compressed air quality matters because low-quality compressors can introduce pollutants like dust, moisture, and oil particles into the airflow. A compressor fills a tank with pressurised air until the pressure inside reaches a target value. After a certain amount of compressed air has been used by an appliance, the compressor will turn on to re-pressurize the tank before it reaches its lower pressure limit.

For optimal performance, the duty cycle, or the ratio of pressurisation time to depressurisation time, should never be higher than 60%. Location is the fourth most crucial element to think about when choosing a compressor and other equipment. Electric vehicles are more affordable and less of a maintenance headache than their fuel counterparts. A compressor's tank size must be adequate for the compressor's output as well as any accessories you intend to use. The location where the compressor will be installed needs to have adequate space and ventilation to keep the device from overheating.

Instead of utilising an extension cord, you might use a longer air hose to save unnecessary energy consumption. If you want to go from FAD to CFM, just divide the former number by 28. If you want to keep the compressor's duty cycle within acceptable parameters, you can't play the air instrument at the same time you're running the pump.

Content Summary

- Finding the Correct Compressor Investing in a high-quality compressor that works well for your needs may help you save money and time in the long term.

- The total air consumption of all your tools that will share the compressor at the same time.

- When looking for an air compressor, it is essential to pay attention to the cabin pressure and quality.

- The most powerful tool's pressure should determine the size of the air compressor chosen.

- With the use of a compressor, air quality can be modified.

- Compressed air quality is a whole different issue.

- Compressor pressure cycles like the diagram below.

- To prevent the compressor from overheating and breaking, the cooling down process must not be hastened.

- The capacity of your compressor, along with any accessories you want to use, will determine the size of the tank you will need.

- One alternative to using a lengthy extension connection is to use a fuel compressor.